The advancement of technology in the 21st century has made it essential for students to be trained in the use of modern tools and techniques. Laser machines are a prime example, as they have become an integral part of engineering and manufacturing processes.

Education plays a key role in training the next generation of technicians and engineers to effectively utilize laser machines. This article explores how laser machine education is helping train future generations to excel at their profession.

We will look at how these technologies can help teach students about robotics, 3D printing, industrial automation, material processing, and more. Furthermore, we discuss how educational institutions need to introduce innovative approaches when teaching these topics while providing hands-on learning opportunities so that learners can gain practical experience with advanced technologies like laser machines.

Overview of Laser Machine Technology

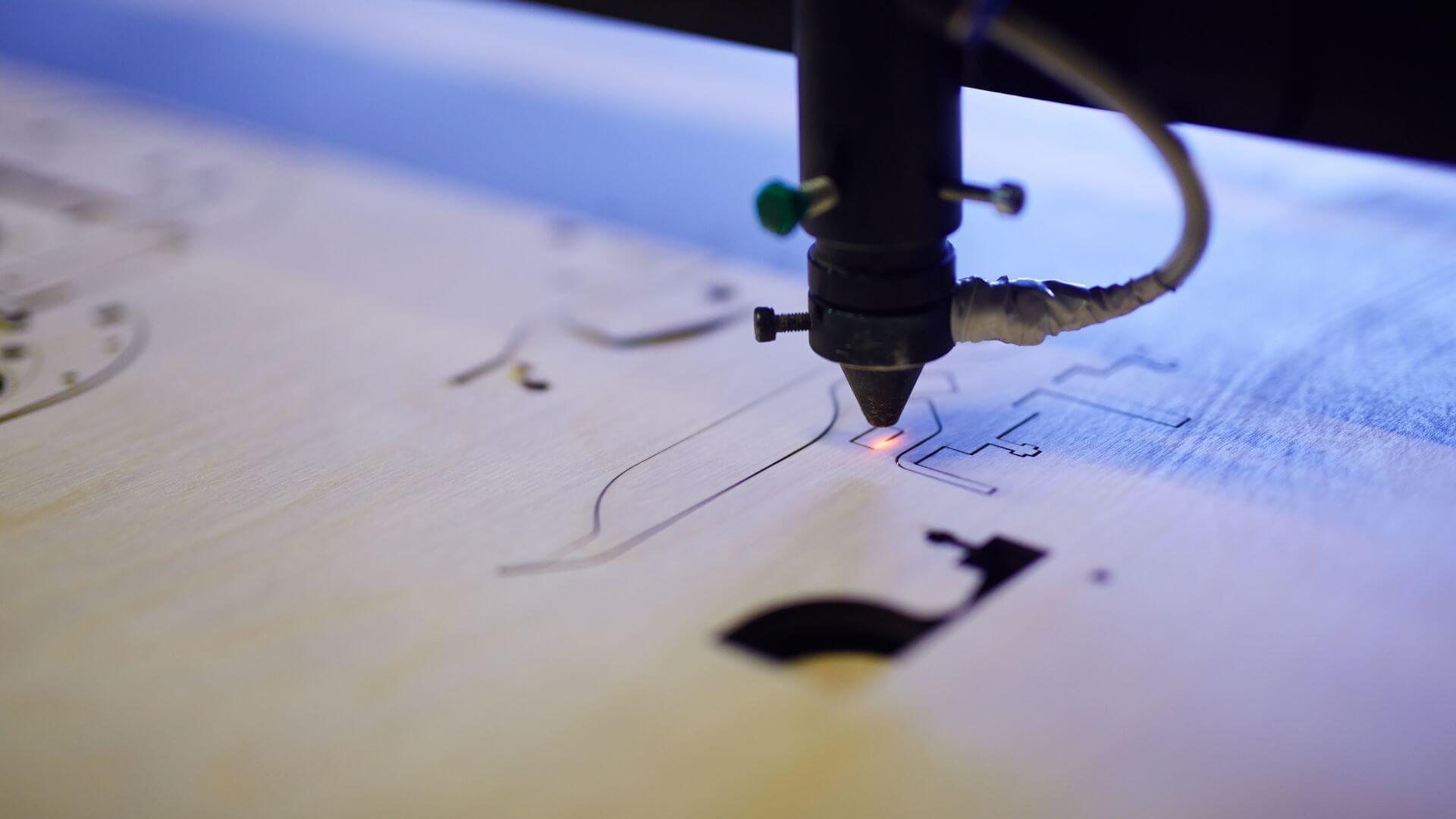

Laser machines are advanced pieces of technology that offer an array of capabilities. From cutting materials to welding parts, laser machines enable precision and accuracy in a variety of applications.

Understanding how these machines work and the different types available is key to successful training for technicians and engineers. This overview will provide an understanding of laser machine technology so future generations can confidently use it in their professional lives.

The basics of laser machine technology involve generating light from electricity which is then used as a heat source to cut or weld material. The energy created by lasers allows for extremely precise cuts with high levels of repeatability due to its highly focused beam size.

Lasers also have broad ranges, enabling them to be used on various types of materials including plastic, wood, metal, stone, and glass among others. Additionally, they can be adapted for other tasks such as marking or engraving products with text or images when equipped appropriately with software toolsets like CAD/CAM systems – making them suitable for many industrial applications. In terms of types available, there are two main categories: CO2 lasers which generate heat through infrared radiation; and solid-state lasers such as Nd: YAG (Neodymium-Doped Yttrium Aluminum Garnet) which produces ultraviolet radiation – both capable of producing powerful beams at a wide range temperatures up to 20kW depending on the application need.

Knowing what type best suits each job is essential knowledge that must be imparted during education programs involving the use of laser technology machinery. This overview has presented some important considerations about the fundamentals behind laser machine technology so that future technicians and engineers can gain knowledge regarding its usage in industry settings – allowing them to become proficient users who will continue advancing this field further into innovative projects far beyond what we know today!

Benefits of Laser Machines

Laser machines offer numerous benefits to students and engineers. They provide a cost-effective way of manufacturing components with great precision, allowing for prototyping and mass production of parts with minimal setup time.

Laser machines also allow for more complex designs than traditional machining methods, enabling quick development cycles that can be used to rapidly prototype new ideas before committing to full-scale production. Furthermore, laser machines are generally easier to use than other machine tools as they require fewer manual operations during operation and have fewer maintenance costs associated with them.

Finally, laser cutting can produce higher quality finished products compared to traditional processes because it produces cleaner edges without any burrs or tool marks left behind from the cutting process. All these advantages make laser machines an invaluable tool in training the next generation of technicians and engineers.

Exploring Career Opportunities in the Field of Engineering

The field of engineering has become increasingly competitive in recent years, making it essential for students to explore all the available career opportunities. The use of laser machines in education is a great way to give aspiring engineers and technicians access to the cutting-edge technology they need to stay ahead of the competition.

With training on these machines, students can gain valuable insights into how they work and develop an understanding of what makes them so important for modern engineering processes. Additionally, career options are broadening due to new developments in laser machine technology.

From prototyping and machining components for industrial applications to creating intricate medical devices or even art projects, those trained in laser machines have plenty of choices when it comes time to decide their future paths. Furthermore, with more businesses investing in 3D printing capabilities, there is even greater potential for skilled professionals within this field who possess expertise with laser cutters and engravers. Therefore, mastering these technologies could open up exciting possibilities that may never have been considered before!

The Benefits of Hands-On Learning Experiences

Hands-on learning experiences can be invaluable for students looking to become the next generation of technicians and engineers. This type of learning allows students to develop practical skills that will help them understand their chosen profession more comprehensively.

By actively participating in activities, such as working with laser machines, they can gain an understanding of how different systems interact with each other and apply this knowledge in real-world settings. Additionally, hands-on learning can foster creativity by allowing students to explore various methods and approaches when solving problems.

They also have the opportunity to think outside the box while developing critical thinking skills which are essential for any technician or engineer. Finally, these experiences provide an immersive environment where students can learn at their own pace through trial and error before implementing solutions on a larger scale.

Ultimately, hands-on learning provides many advantages for those seeking careers as technicians or engineers.

Conclusion

Laser Machines are an invaluable tool for training the next generation of technicians and engineers. Technology is leading us into a new era where students have access to cutting-edge technology that can help them learn and build their skills faster than ever before.

By using lasers in educational settings, students gain experience working with complex machines while receiving personalized instruction from experienced professionals. With this combination of education and hands-on experience, laser machine training provides students with the vital knowledge needed to succeed as technicians or engineers in today’s competitive job market.